Most people think that yarn made from wool is woollen, and in a general sense that’s not wrong, but for those of a fibre or textile persuasion it’s a lot more complicated than that, and this is just one aspect of the many things in the magical and wondrous world of wool, more will follow!

To go back to very beginning most sheep produce usable wool in some way or another, there are hundreds and hundreds of different breeds of sheep and the colour, the quality, and quantity of wool produced is very varied.

Man first started using whatever wool the sheep provided , but it wasn’t long before a gentle process of selective breeding came into play to provide the best wool or indeed the best meat, it wasn’t always possible to get both at the same time.The many breeds of sheep give varying lengths of fibre, many sheep give fibres between 2″ -4″ which is an excellent basic wool but the most highly prized is the longwool bearing sheep which can give fibre of up to 12″ or perhaps even more.

It is possible to spin directly from the fleece, but most spinners will clean or prepare the wool in some way to make the next process a little easier.

General purpose wool for general purpose use is most likely to be carded after cleaning, producing a random mix of shortish and longish fibres, usually jumbled together loosely, what hand spinners call rolags. This uses almost all the available fibre with very little waste and is ideal for spinning yarn that is going to be used for knitting. There are different ways of spinning woollen yarn but handspinners use rolags, a loose sausage like roll of fibre, often some version of a longdraw method is used, this produces an open, soft and fluffy yarn, not always the strongest but excellent in making things for warmth. This type of yarn is called Woollen ( often woolen in the United States).

Long wool fibres can not be easily carded, they are simply too long and get caught up on the drum, so are combed instead using long spiked boards which separate the long and shorter fibres. The long ones are kept, shorter ones put aside and can be carded to produce a woollen type yarn, and spun into yarn using a shortdraw technique which produces a finer, harder and more even yarn which took the name of a village in Norfolk ( apart from a curious spelling change) Worsted. This method of spinning is a little slower, but the higher price obtained more than offset the difficulty.

English worsted spun yarn was highly sought after and helped to create the importance of the wool industry in England in the 12th century

This is only a very quick view of the differences and there is a huge range between woollen and worsted yarns, infact many hand spinners produce something in between. Purists will always want the Worsted yarn to be very specially prepared with cut ends always in the same position, but this is seldom possible in practise in commercial preparation, so the word semi-worsted abounds in spinning parlance.

Woollen yarns are ideal for knitting, the yarn is very open and will help to make cosy and warm fabrics, often by knitting, but could be used in weaving loftier cloth such as tweed. All the fibres are all used so the yarn isn’t completely smooth, fine, or strong but it is a very economic use of wool as almost all the fibre is used.

Worsted yarns are ideal for weaving, the yarn is thin and strong and makes excellent cloth for suiting and fine goods, it is more expensive as only the best/long fibres are selected so generally thought of a prestige product.

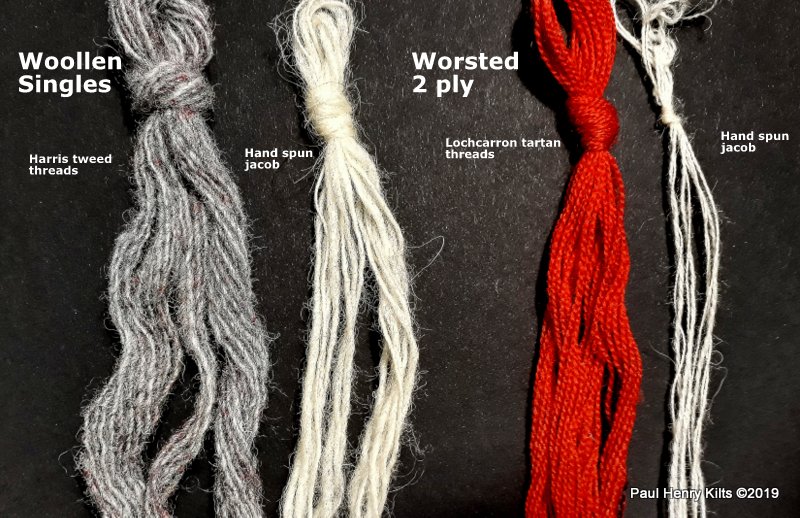

Here is an easy to understand ( hopefully) photo of examples of both commercial and hand spun woollen and worsted yarns,

The Harris tweed ones are typical in their mixed colours,fairly thickly spun but they pull apart with ease pictured alongside some jacob fibre – spun from a rolag with a long draw, similar weight, both fairly typical of a general purpose yarn.

The Lochcarron tartan ones – a leading tartan weaver – are very finely machine spun with a hard twist and can be separated with patience alongside the jacob – spun from a combed preparation with a short draw, actually a little bit finer that the Lochcarron, but much slower to spin than the woollen one, another reason for the extra price of a worsted yarn